Under the TLUH Program TUSAS has completed design, development and the manufacture of an indigenous twin-engine, 5-ton class medium category (4 to 6 tons), utility helicopter with a maximum take-off weight (MTOW) of 6,050 tons and powered by a pair of 1,400 shp class turboshaft engines. Powered by a pair of LHTEC CTS800-4AT turboshaft engines, each generating 1,373 shp during take-off, the T625 TLUH first prototype (dubbed P0) performed its first flight, which lasted 20 minutes, on 6 September 2018 at 6:00am at TUSAS facilities in Ankara. According to Honeywell the CTS800-4AT has almost 95% commonality with CTS800-4A engine, which is being used on T129 Mk-I ATAK helicopters and the 5% difference stems from necessary modifications on the engine and FADEC system (Full Authority Digital Engine Control) System to meet the T625 specific requirements.

Under the Prototype Phase Turkish Aerospace will manufacture three prototypes for flight and ground tests, and to power these helicopters 10 CTS800-4AT turboshaft engines have been ordered from Light Helicopter Turbine Engine Company (LHTEC, a 50-50 partnership between Honeywell and Rolls-Royce) under a contract signed on 10 December 2015 between TUSAS and LHTEC. According to Honeywell as of May 2019 six of these 10 CTS800-4AT engines have already been delivered and the remaining four engines (expected to be used as spares and for ground testing purpose) are scheduled to be delivered during 2019.

The production of T625 GÖKBEY helicopters are initially expected to be powered by a pair of LHTEC CTS800-4AT turboshaft engines, but once all tests are complete and the required certification is obtained, the serially produced T625 GÖKBEY helicopters will start flying with indigenous TS1400 engines (in 2024-2025 timeframe), which are being developed domestically by TUSAS Engine Industries Inc. (TEI) under the Turboshaft Engine Development Project (TEDP). The TS1400 Turboshaft Engine can also be integrated into the T129 Mk-I ATAK Helicopter with some adaptations.

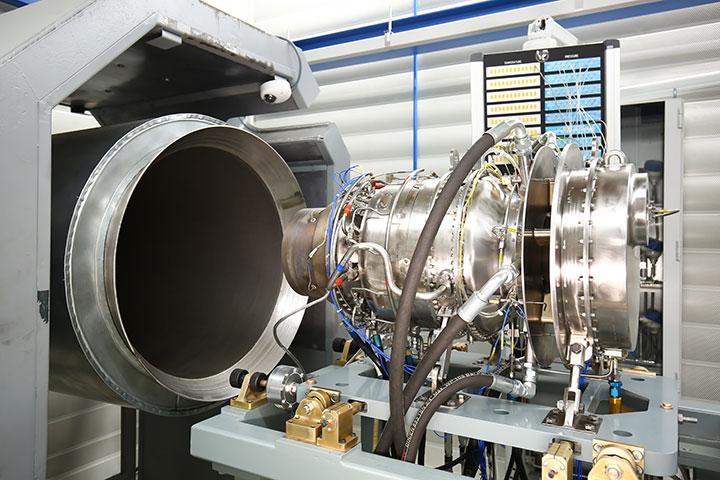

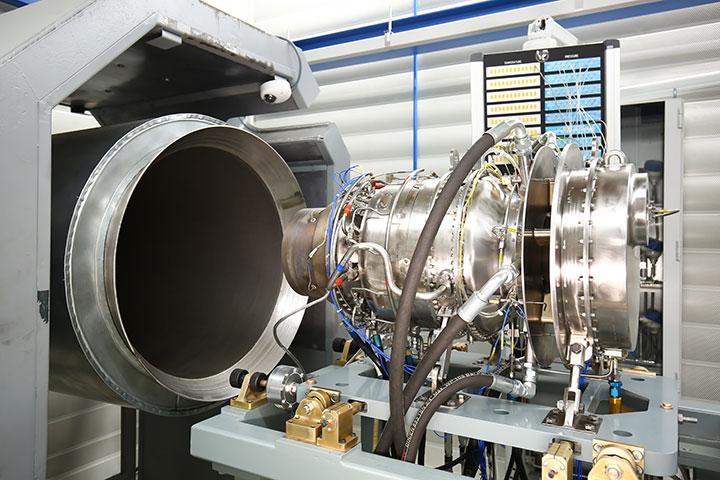

On February 7, 2017, TEI was awarded a contract by the SSB under the Turboshaft Engine Development Project to develop Turkey’s first indigenous turboshaft engine to power the T625 GÖKBEY TLUH. Under the eight-year (2 years for the development of the turbojet core + 4.5-years for the prototype manufacture + 1.5 years for certification) schedule TEI is to design, develop, produce and certify two 1,400 shp turboshaft engines (TS1400, ITAR-free) prototypes with a team of 250 engineers. The preliminary prototype of the turbojet core to be used on the TS1400 engine which was successfully tested for the first time on a test bench on 11 June 2018. The test cell, where the TS1400 Core Engine Tests are being conducted was designed, manufactured and made ready for use with fully domestic achievement in cooperation with the 1st Air Maintenance Factory Directorate and TEI.

According to the information we have obtained, 12 to 14 TS1400 prototypes will be produced by TEI under the 8-year Turboshaft Engine Development Project including the core engine prototypes.

During the Concept Development Phase of the TEI TS1400 Engine, 10 different engine models were examined and the centrifugal (radial) flow compressor design, which is more suitable for the turbocharger, was adopted. Axial compressors, on the other hand, are generally preferred for turbojet engine designs. For example, the Kale ArGe Company product KTJ-3200 Engine, and the French Safran Power Units’ (former Microturbo) TR-40 Turbojet Engine features four-stage axial compressors. With the centrifugal design, higher mass flow rates can be obtained in narrower spaces (shorter engine length), however, the centrifugal compressor design requires larger engine diameter than the axial compressor design. The axial flow compressor engines are smaller in diameter, but they are notably longer. Centrifugal compressor engines are considered more robust and stable, while engines with axial compressors are more fuel-efficient than the centrifugal compressor engines. Since the aim of the TS1400 design is to develop a turboshaft engine rather than a turbojet engine, a centrifugal flow compressor design was chosen because the shaft power is more important than the propulsive power (thrust).

The TS1400 Engine consists of a two-stage Centrifugal/Radial Compressor, a Reverse-Flow Combustion Chamber (Combustor), a two-stage High-Pressure Turbine (HPT) and a two-stage Power Turbine (PT). The 2nd core engine prototype in turbojet configuration, which was previously exhibited at IDEF 2019 as well as at the Istanbul Air Show (AIREX) and at the 4th High-Tech Port by MUSIAD in 2018, has an exhaust vent at the rear section instead of a Power Turbine. Power Turbines are required for the transition of the core engine in turbojet configuration to both turboshaft and turboprop configuration.

The turboprop version of the TS1400 Turboshaft Engine is planned to power TUSAS HURKUS-B/C aircraft. In the turbojet configuration of the TS1400, the core engine can also be converted to turbofan configuration by adding a fan and additional shafts and bearings to the front side and a power turbine to the rear side. Turbofan engines have 30% to 40% lower fuel consumption rates compared to the turbojet engines; however, their production is more difficult, and their unit costs are more expensive than turbojet engines. For example, the unit price of an F107-WR-402 turbofan engine is US$190,000, while the unit price of a turbojet engine in similar class/thrust rates is around US$100,000.

Among the main purposes of the Turboshaft Engine Development Project (TEDP) is the establishment of a gas turbine engine design and the development of infrastructure and the knowledge to facilitate such a development process. Thus, the core technology of the TS1400 Engine shall also form the basis for the indigenous turbofan engine (in 8,500lbf to 9,500lbf thrust class) needed for the HURJET New Generation Advanced Jet Trainer (AJT) & the Light Attack Aircraft Development Project, and it will be possible to develop the national aircraft engine when needed, upon any necessary technological additions to the capabilities gained under the TEDP.

However, the TS1400 engine, which prefers a two-stage centrifugal compressor like the LHTEC CTS800-4AT engine with a high-level weight and volume optimization, requires axial (front) air intake assembly changes that are necessary for a turbofan engine design. Although extremely suitable for turboprop (TP) or turboshaft (TS) engines, the two-stage centrifugal compressor architecture has some disadvantages in terms of the cross-sectional area due to both the bypass ratio (the ratio of the air that goes through the core, i.e. the capacity) as well as the placement of the radial air assembly and the combustion chamber. The TS1400 is anticipated to be developed further with a multi-stage axial flow compressor and then a single-stage centrifugal compressor assembly to be able to evolve into a high-performance, low-thrust turbofan (TF) engine. Announced by TUSAS General Manager Dr. Temel KOTİL during the IDEF ‘19 Fair for the first time, the indigenous 2,500-3,000 shp turboshaft engine, which will power the T129 Mk-II (ATAK-II) Heavy Attack Helicopters, can be expected in a similar configuration.

According to TEI, the TS1400 Engine has a more robust design thanks to the centrifugal compressor assembly. It allows the air to flow through the core from front to top, not from front to back, creating more efficient negative and positive pressures. Under the TEDP, TEI has been able to effectively produce TS1400 core engine prototypes within two years following the contract and plans to perform the first flight test on the T625 GÖKBEY helicopter in 2021.

Although the contract was signed in February 2017, the history of TEI’s knowledge and infrastructure accumulation for the TS1400 engine goes back to the Core Engine Technology Development Project that was launched in July 2012 with a 3-year schedule. The aim of the project was to develop core engine technology, which would form the basis for a 1,000 hp class turboshaft engine. Under the project, conceptual design software & methodologies for the indigenous compressor, combustion chamber, and turbine were developed by studying different engine architectural concepts. The detailed design studies on the TS1400 started in 2016. The oil lubricated TS1400 engine also features an indigenous FADEC System. The two TS1400 engines on the T625 GÖKBEY will be able to communicate with each other via FADEC. For example, if an engine experiences power loss during the flight, the other engine will be able to increase its power to compensate the lost power of the other engine. The standard engine power of theTS1400 will be 1,400 shp (shaft horsepower) but it will also have the capacity to produce 1,660 shp for a period of 30 seconds in an emergency, such as in the case of the loss of another engine.

The TEI TS1400 engine is expected to have similar dimensions and weight with the LHTEC CTS800-4A/4AT Turboshaft Engines, which have a reputation for compactness, light weight, reliability, power and durability. In open sources, the dry weight of the LHTEC CTS800-4A Engine (with a length of 86,4 cm and height of 72,9 cm) is stated to be 360 lbs. (163 kg). According to the EASA Type Certification Data Sheet the CTS800-4N version, featuring a reduction gearbox compared to the CTS800-4A/AT versions, with an overall length of 122,2 cm overall width of 60 cm and overall height of 72,9 cm has a dry weight of 408 lbs (185,1 kg). The TS1400 Engine will ensure the shaft output speed conditions of 23,000 rpm and have a service ceiling of 20,000 ft. The process which starts from the engine right through to shutting it off again is known as a cycle, and over the engine’s lifetime there are only a finite number of cycles before something cracks or breaks. The conventional methodology for measuring this lifespan and one that’s used by many engine manufacturers is known as the TAC (Total Accumulated Cycles) Life. One TAC is the equivalent of one cycle of an engine (exactly: one excursion from engine start, passing intermediate power rating and back to engine stop). The average lifespan of the TS1400 is expected to be at least 2,500 cycles, while the target for the service life is 5,000 cycles (TAC). After 2,500 or 5,000 cycles the TS1400 will require a general overhaul.

A team of approximately 250 engineers, all of whom are TEI employees from TEI’s Eskişehir, Ankara and Istanbul Engineering Offices, are involved in the project. The TS1400 turboshaft engine design team includes engineers from the fields of Aerothermal Engineering, Structural Engineering, Product Engineering, Prototype Testing, Electrical/Electronic & Control Engineering, and Embedded Systems Engineering